|

"The ITTF has recently announced that glues

containing volatile organic compounds (VOCs) will be banned as of January 1,

2008, in ITTF junior events and as of September 1, 2008, in all other ITTF

events (ITTF

Announcement).

Falco Tempo Unlimited speed

glue is one of the first VOC free glues on the market. Water-based

VOC-free speed glue is now a reality!

NOTE: This is a LONG LASTING speed

glue, the effects are reported to last between 1 to 3 WEEKS!

Instructions for use (as described on the tin):

- SHAKE WELL BEFORE USE.

- Put the glue on the rubber and the wood.

- Apply one layer and wait 6 hours before applying a

new layer.

- Let dry at least 24 hours in a dry place and at room

temperature.

- Assemble the rubber and the blade. "

Warning: This product (and all other speed glues and

alternatives) stretch the rubber, increasing the tension on the topsheet. Some

high tension rubbers or Tensors are not designed to be used with speed glue or

alternatives as it put too much tension on the topsheet. Some rubber are glued

together better than others, so using speed glue or alternatives, there is

always a risk of damage to the rubber.

Review and procedure:

Review by Alex:

1. Impression of the glue:

The tins are similar to the those used for other long lasting glues like Tibhar

Rapid Clean Deluxe (RCD) and seals very well. The glue looks whitish and is quite thick, a little thicker compared to my

Tibhar RCD. The smell is not very strong, and certainly does not have the strong

solvent smell. It reminds me a little of the kids glue for gluing paper and

stuff together.

2. Testing the glue on a new rubber:

I figured the best way to test this glue was to test it on a rubber that I'm

used to and know really. So the test are performed on a new sheet of Globe 999

National. Although normally before I speed glue a rubber I would prime it, but

priming with normal glue or speed glue could affect the performance, so I

decided not to prime, and accept that the performance may not be as good, or

take a while for the rubber to peak...

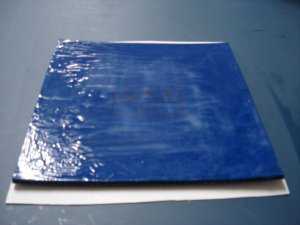

Ok, here is a picture of the rubber unglued. Note it has a slight inwards

dome. The plastic protection sheet is still on the rubber.

3. Applying the glue:

Ok, time to apply the glue. I shook the tin a little as recommend, and spread

out a single brush-full of the glue over the sheet. I immediately noticed that I

probably should have shook the bottle a lot more, since the white and

transparent liquids had not mixed that well. I tried to mix it as well as I

could on the rubber. You can see from the picture that some areas are still a

little more whitish than other, but it's pretty good and hopefully won't affect

the results too much. So NOTE: follow the instructions on the tin well, SHAKE

before use!

4. After the first waiting period

The instructions recommends a 6 hour period before

the next layer. I decided to do 2 layers of glue, so that I could compare it to

the 2 layers of Tibhar RCD glue that I normally use. I didn't get

around to looking at the sheet until about 8 hours later, but this probably

does not matter much since drying times were long anyway. So here is the sheet

after 8 hours of drying:

The dome is quite good, at least as good as with my Tibhar RCD glue, so I was quite

impressed so far. The surface looked dry and felt sticky.

5. The second layer

So I decided to put another layer on (as was the plan). I used a thinner

layer this time since the dome was already pretty decent, but enough to wet the

whole surface again.

Within minutes I could see the dome increasing again already. Since I was

getting a little concerned to put too much stress on the topsheet with the

plastic protection sheet still on, I decided to remove it. Well the dome

increased by a fair more immediately, I was impressed! I started to wonder if

the second coat may be necessary at all...

The sheet felt a lot more flexible already too, the initial stiffness of a new

sheet seemed to have disappeared. Persumable this was due to the combination of

stretching and the softening of the sponge.

6. Apply glue onto the blade

At this point I also needed to put glue on the blade, as it required 24h of

drying before the rubber and blade should be put together. So I put a thin layer

of the same glue on the blade.... At a later stage I'll experiment to see if

normal glue can be used for this, to save the use of the more expensive Falco glue:

7. The next waiting period

Another 8 hours later, here is what the rubber looked

like:

The dome had not changed much, perhaps slightly more, the 2nd thin layer may not

have made a lot of difference. The surface felt quite dry but very sticky.

The blade has dried a little around the edges, but still seemed fairly wet in

the middle. The part that had dried didn't really feel sticky very much but

might still be enough to get the job done.

8. After the final waiting period

Ok, the next morning, another 10 hours later or so I

inspected the rubber and blade... To my surprise the dome had gone down:

I can think of 2 likely reasons for this

1. The glue has made the rubber a lot more flexible and softer, so the sheet can

no longer hold up the dome and has sagged down.

2. It's been 24 hours after I applied the second coat, and this coat was quite

thin, possibly too thin, so the rubber has been left to dry too long, ie 36

hours since the initial thick layer, which is what it requires...

The sheet looks quite dry and is quite sticky, here is a close-up:

The blade surface has almost completely dried, but only feels very mildly

sticky... hopefully it's enough. In a few spots it still looks a little wet, but

it feels thick and sticky so it should be OK. The weather has been cold and

humid, so drying conditions are far from ideal....

9. Time to assemble rubber and blade

Ok, time assemble the rubber and blade...

I put the rubber onto the blade and rolled it with a roller as usual. It stuck

down very well, no trouble at all. The topsheet looked in perfect condition, and

was not affected in any way by the glue.

Feeling the rubber on the bat, the sponge definitely felt a little softer, but

not nearly as soft as my other rubber, which had been 'super primed' and had

been glued about 4 times. I don't think it's a lot different to the first time I

glue with my Tibhar RCD, it always takes a few gluing to soften it up...

10. The first test run.....

I compared it side by side with an identical rubber and blade, the other rubber

had been 'super primed' and had been glued up with Tibhar RCD glue 4 times

before, so this was well and truely 'worn in', which should be taken into

account...

Well the rubber certainly had a decent speed glue effect. My loops were a fair

bit faster, and definitely spinnier too. I don't think it was quite as fast as

my other rubber, but not that far off. I could not feel the ball dig in as much

as my other rubber, but I WAS getting very good spin. It felt like I was getting

more spin from the topsheet... the feel was just a little different, but not

hard to adjust to.

What I did notice also was that it was louder than my other rubber. These Globe

999 Nat rubbers are fairly firm, and my blade fairly soft, so there is not

normally a lot of sound (I'm referring to the the speed glue click sound), but

this rubber with the Falco glue was definitely louder than with my Tibhar glue.

This could well impress other players with soft sponged rubber...

The rubber did not feel a lot different to a new sheet that was glued with my

Tibhar glue for the first time... so this is very encouraging.

All in all I was quite happy, and I'm confident that this glue will do the job

when I decide to stop using VOC glues. I find the Globe 999 Nat too hard to

control without glue, as some softening of the sponge and a bit of a stretch is

required, which is exactly what glue does. Well the Falco glue certainly does

this, and hopefully will get even better over the next 1 or 2 gluings...

11. The next step

Next I will take the rubber off the blade and let it shrink back, and re-glue it

again the next week (the effect will probably take a week to wear off), and see

how it performs now that it's got some glue in the sponge, and has had a good

stretch, which most Chinese rubbers require before they peak....

Priming the rubber with 1 or 2 thicker layers before use, and letting it have a

good stretch, may well improve the performance as well, this is something else

I'll have to investigate. If the performance of the rubber is significantly

better the second time around, then priming is almost certainly the way to

go.... The optimum priming method will need to be investigated too.

Click here for pricing / purchase Falco Tempo unlmited from One of a

Kind Trading Australia |