Part1: Super Priming

Step 1 - Preparing the rubber

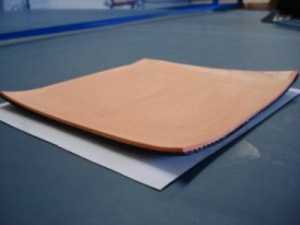

Firstly remove the rubber from the packet and lay it down

onto the table. If you have a Chinese rubber please remove the plastic

protective film on the topsheet and place a piece of cardboard under it to keep

the tacky topsheet from adhering to dust or glue stains. Make sure the cardboard

is blank so that the tacky surface of the rubber cannot pull off any bits/ink

off, or theyíll end on your rubber. If you have European or Japanese style

rubbers (non-tacky), then this wonít be a problem. Note that sometimes rubbers

already curl up a little (as pictured) or sometimes they are flatÖ it does not

matter.

Step 2 - Preparing the blade

If the blade is brand new, itís best to seal it with some

sort of polyurethane (or varnish or shellac) coating. Only a very thin layer

should be used, enough to protect the top fibres on the surface, but not too

much to affect the feel of the blade. The easiest and most convenient method is

to just use hairspray. Almost all hairsprays contain polymer acrylates which is

basically what holds your hair in place. When sprayed onto the blade it creates

a really thin layer on the surface, which in effect protects it from splintering

but wonít affect the feel of the blade.

The only wood that probably doesn't need sealing is Hinoki. If you

have a hinoki blade then you can skip the sealing.

If you have a old blade thatís been glued many times,

chances are that its got glue stains on it. Although this isn't a major problem

its best to clean it all off.

Step 3 - Applying Glue

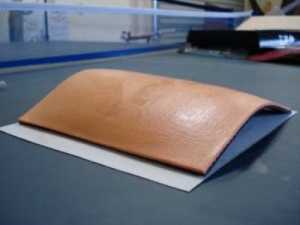

3a. Apply a layer of normal glue onto the rubber covering

the entire area. Once you applied the first layer, the rubber may have a bit of

a dome (curls up) by now, which is fine. Leave it for about 10minutes or until

itís touch dry. Apply another layer and wait again. As you can see from the

picture, the rubber has flattened out, whereas it was curled before. If it had

been flat to start with, it would have curled up.

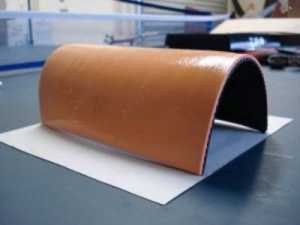

3b. Now place 4-5 layers of speedglue (wait for each layer

to be touch dry before putting on the next) on the rubber. Pictured after 2

layers and after 5 layers:

On the 5th layer while the glue is still wet, roll it onto

a glass plate and stack about 5kg's of books on it overnight.

Pictured rubber put onto the glass, and rubber under books:

Important Note: Using this many layers

of glue can put quite a bit of strain on

rubbers, so if youíre not confident that the topsheet and sponge are glued

together well, use less layers, or at least enough layers to get a decent dome.

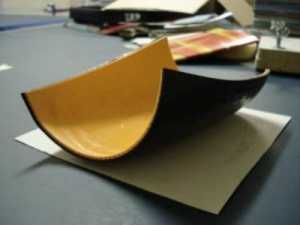

3c. In the morning when you peel the rubber off the glass

plate. There should be a reverse dome instead of the kebab the night before. The

rubber is already much bigger at this stage.

This next stage is crucial as the rubbers size will not

stay that way permanently. Repeat step 3b with the 4-5 layers of speed glue

again and leave it for 3hours onto the glass plate (for best result Overnight is

the best). Pictured after another 5 layers, and after putting onto the glass

plate for a second time.

Next apply a thick layers of glue to the blade and spread

it uniformly across the surface. Once this is done leave it to dry.

Step 4 Ė putting the rubber onto your bat

Once the blade and rubber has dried completely, align the

rubber from the bottom and roll (with a bottle or roller) it upwards onto the

blade very gently. If you roll it hard it will stretch the rubber and alter its

characteristics. Once itís glued onto the racket. Roll it a few more times

just to make sure there are no air bubbles. Use a sharp blade to cut the rubber

and finally place it in a clamp for about an hour.

Note: Cut SPARINGLY meaning leave excess/overhang just to

make sure as some rubbers tend to shrink a few mm's back when they've calmed

down over a few days. This wonít happen if you've been patient. I find that if

you rush and hurry up the whole process. Then it normally shrinks back but in

return, the rubber is faster, softer and springier, but itís not at the

pinnacle as when you follow the instructions exactly.

Part 2 Ė Super Priming using Normal Gluing

Below is a series of steps that should be followed to give

you a long lasting solid gluing. This is only for the players that don't like,

or choose not to use speed glue and prefer to keep their racket unglued and

ready to play at any time.

Step 1 - Preparing the rubber

Firstly remove the rubber from the packet and lay it down

onto the table. If you have a Chinese rubber please remove the plastic

protective film on the topsheet and place a piece of cardboard under it to keep

the tacky topsheet from adhering to dust or glue stains. Make sure the cardboard

is blank so that the tacky surface of the rubber cannot pull off any bits/ink

off, or theyíll end on your rubber. If you have European or Japanese style

rubbers (non-tacky), then this wonít be a problem.

Step 2 - Preparing the blade

If the blade is brand new, itís best to seal it with some

sort of polyurethane (or varnish or shellac) coating. Only a very thin layer

should be used, enough to protect the top fibres on the surface, but not too

much to affect the feel of the blade. The easiest and most convenient method is

to just use hairspray. Most almost all hairsprays contain polymer acrylates

which is basically what holds your hair in place. When sprayed onto the blade it

creates a really thin layer on the surface, which in effect protects it from

splintering but wonít affect the feel of the blade.

The only wood that doesn't need sealing is Hinoki. If you

have a hinoki blade then you can skip the sealing.

If you have a old blade thatís been glued many times,

chances are that its got glue stains on it. Although this isn't a major problem

its best to clean it all off.

Step 3 - Applying Glue

Apply a layer of normal glue onto the rubber covering the

entire area. Its best to apply layers that aren't too thin or thick but just

right. Once you applied the first layer, the rubber may have a dome (curls up)

by now, which is fine. Leave it for about 30minutes so the dome goes down. Note:

sometimes this is longer for different rubbers. Repeat this gluing procedure at

least 3 times. Then leave it for 2 hours so most of the glue effect and dome

evaporates.

Next apply a thick layers of glue to the blade and spread

it uniformly across the surface. Once this is done leave it to dry.

Step 4 - Putting it all together

Once the blade and rubber has dried completely, align the

rubber from the bottom and roll (with a bottle or roller) it upwards onto the

blade very gently. If you roll it hard it will stretch the rubber and alter its

characteristics. Once itís glued onto the racket. Roll it a few more times

just to make sure there are no air bubbles. Use a sharp blade to cut the rubber

and finally place it in a clamp for about an hour.

Part 3 - Speed Gluing

Below is a few steps that should be followed if you wish

speed glue effectively and have a considerable effect on your rubbers.

Types of glues

To me there has always been 3 types of glues. At the time

of writing this, the VOC glue ban has just been brought into effect, and not

many manufacturers have released VOC free glues yet.

1. Normal glue - Minimal speed glue effect, gives very good

adhesion for sticking new rubbers on. Also great for long pips to give a solid

gluing.

2. Speed glue - At the moment there are tonnes of varieties

of speed glue on the market. Each has a slight difference in composition which

makes it perform in a different way. Itís impossible to name them all and list

their characteristics. So basically, if it isn't normal glue or long life glue,

then its speed glue.

3. Long life Speed glue - These glues, commonly (and

incorrectly) referred to as Ďwater based gluesí, have entered the market for

a few years now with varying success. They provide the user with close to 4 days

of the glue effect without the hassle of gluing every 3 hours. These glues can

take up to 12 hours to dry before they can be attached onto the blade. They

smell a little really peculiar, some with a distinct fruity type smell.

At the moment I know of Butterfly Millennium chack, Donic

Enduro, Yasaka Pro-Life and Tibhar Rapid Clean Deluxe. These glues all belong to

this category and provide a long life speed glue effect. As far as I know they

are also all made in the same factory in Belgium, and the difference between

them is not huge.

Gluing techniques.

Everyone glues differently so there are many methods of

gluing around. I'll just list the 2 that I think are the most effective. These

apply to the normal speed glue only:

Technique 1.

Apply the glue evenly on to the rubber. Wait until a layer

is touch dry before adding the next layer. The more glue and layers, the more

effect. Once itís dried, put a thin layer on your blade, wait for it to be

touch dry, and just attach to your blade and clamp it for a few minutes as

usual.

Technique 2.

Apply the glue onto the rubber, and while its still wet

place and clamp the rubber sponge side down onto a glass plate. By doing this

the fumes of the glue are trapped and can only permeate through the sponge. This

method allows maximum glue effect with minimal glue usage. The only downside is

that it takes longer then the above method. Leave the rubber on the glass plate

for about 10-15 minutes, when you peel it off there should be a considerable

dome. If your not happy with the results, then do it again until you get the

desired effect. Once your happy, glue it onto the blade and clamp it.

Part 4: Removing Glue

This section is intended for those that speed glue quite

often and have to deal with glue build up. After about 10 or so gluings the

additional layers don't penetrate the sponge as well thus not giving you the

optimum glue effect. The ideal solution to this is to buy a new rubber (if your

sponsored, shouldnít be a problem). More commonly though itís quite easy to

remove the glue build up so you have a fresh sponge to work with again.

1. Using speed glue to remove glue.

If you have a rubber which has a fairly medium to hard

sponge, then this method is ok. Basically apply a layer of speedglue onto the

build up and spread it around very thoroughly. Doing this sort of dissolves the

glue already present on the sponge. About 2 minutes after the application you

can start to rub the glue off the sponge with your fingers. Do it gently and

take your time. If the glue starts to harden up again, use a additional layer of

glue. If your careful, there should be no damage and the rubber will be

immaculate. More commonly if you rush, you can expect to take bits of sponge off

and end up with a mess.

I do not recommend this method with soft rubbers as it will

most likely destroy them.

TIP: If you use long lasting speed glue to do this,

everything becomes easier as that type of glue stays semi solid for much longer

making the whole process easier. Only downside is that it's a waste of precious

glue.

2. Orange Oil

This method basically involves the use of Orange Oil which

is basically a air freshener that can be found in your local supermarkets. The

key ingredient that makes it work is citric acid. If you find any other air

fresheners that contain this, it should work. The Orange Power that Ive been

using for that last 3 years comes in a orange bottle with a purple spray twist

top on it and it sells under the name "Orange Power".

The method is basically the same, spray on 2 layers of the

stuff onto the sponge and wait around 5 minutes for it to be touch dry. The glue

build up should be dissolved and semi-solid. You can easily rub the excess build

up off compared to method 1. If you take too long and the build up hardens. Then

spray another layer.

This method works on any rubbers and works very well with

super soft rubbers that are prone to damage. The only downside is that it may

tint your sponge a slight orange and it may smell like oranges which isn't such

a bad thing.

3. Miscellaneous Methods

Eucalyptus oil, WD40(Grease remover), Ironing, dry rubbing

with thumb. These are all methods I have heard of but they dont work as good.

Eucalyptus oil - This stuff absolutely reeks and leaves a

terrible smell to everything. No doubt it works but the smell alone is enough to

set anyone off.

WD40 - A sworn method of a select few, but I have yet to

try it myself

Ironing - Basically placing a A4 sheet of paper on the

sponge, and then proceed to iron it until the glue melts and is collected on the

A4 paper. I've tried it once and it doesn't work for me. All I was left with was

a pile of molten rubber and paper stuck to the sponge.

Dry rubbing with thumb - some hardcore players out there

reckon they can remove glue just by peeling it or rubbing it away without the

aid of solvents. This is possible with extremely hard sponges that are damage

resistant. Chinese blue sponges also allow this method to work quite easily. Be

aware that trying this method on any other sponge is most likely to cost you a

new rubber.

Copyright © 2007 LawOCG and haggisv

|